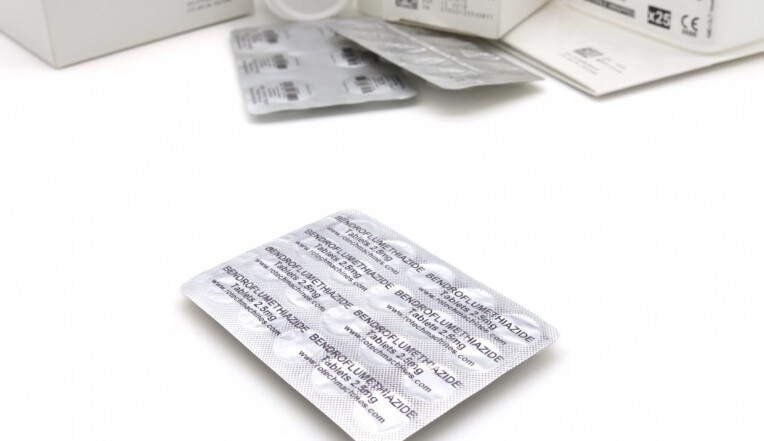

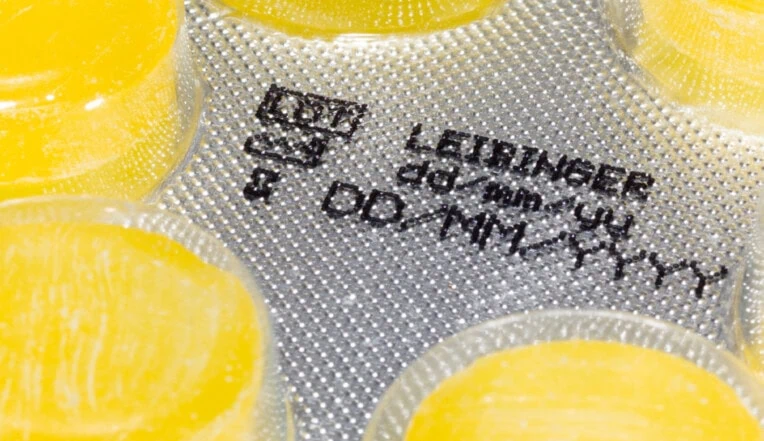

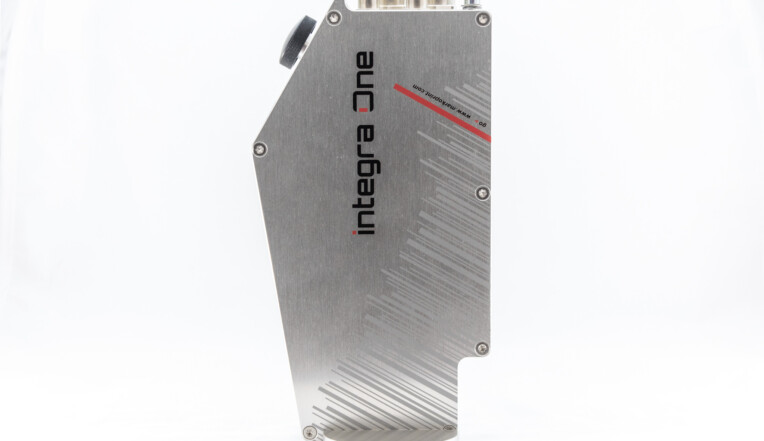

Print excellent quality codes and variable data onto blister cards

One manufacturing site can often use hundreds of variants of blister cards, the only difference being the information printed on it. Generally, blister cards are a regular shape, flat, easy to print onto and capable of being handled at high speeds.