In a nutshell

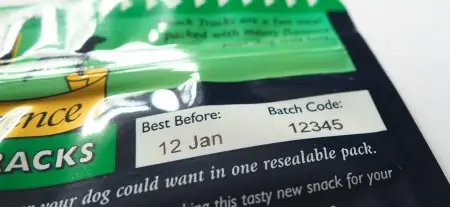

Although coding your products and packaging on-line is nearly always favourable for ease and efficiency, it’s not always the best solution. For some applications, coding away from your production line (off-line) is the preferred method, offering flexibility and dependability where needed.

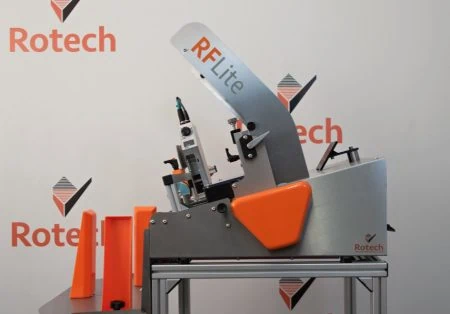

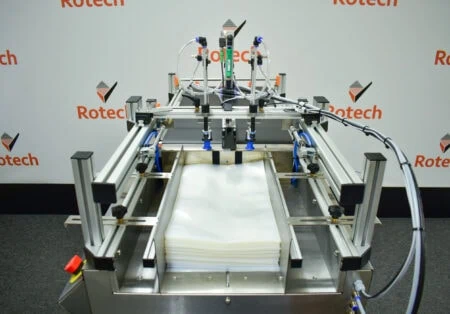

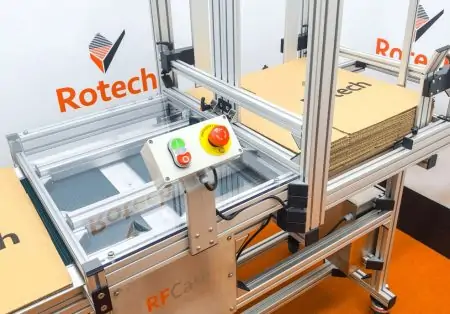

Our RF range of feeding systems have been designed to handle any flat-form product or packaging, and can be fitted with a variety of coding & marking technologies to suit your individual application needs, no matter how small, big or complex.

Take a look at our comparison table below to find out which feeder may best suit your application.