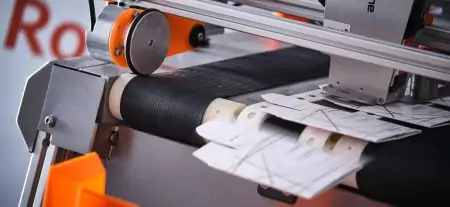

The RF Pouch is a unique solution for the automatic feeding, printing and/or labelling of resealable pouches, polybags and asymmetrical products. Using vacuum technology, the system picks up the flexible pack with ease, places it onto the conveyor for printing and/or labelling, before transferring the marked pack neatly onto another stack, ready for operator collection.

RF Pouch

Specialised pouch feeding system, to code or mark flexible or asymmetric products

Benefits

Reliable

Accurate

- ‘Pick and place’ system for reliable feeding of pouches or bags

- A range of belts and vacuum cups available, to suit your application needs

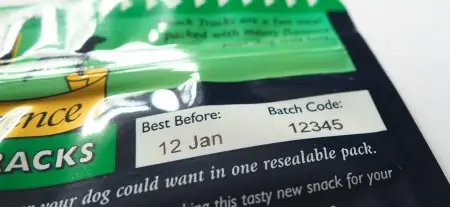

- Auto code facility for automated date code generation

- Servo version available for intermittent motion applications

- Ability to add inspection systems

- Anti-static add-ons are available

Versatile

- Can handle a wide range of bags and pouches

- Can accommodate TTO and TIJ printing technologies

- TTO printing in continuous mode, for greater throughput and print area

- Can accommodate all types of labelling system, including print and apply

- Labelling and printing combinations possible

- Adjustable catcher-tray for easy removal of printed product

Full UK Support

- Designed and built in the UK

- Installation and training can be provided, UK-wide

- Almost 200 combined years of industry knowledge

- Our friendly and knowledgeable support team are always on hand to offer you assistance when needed, whether that be with a service visit or a quick call over the phone

- Preventative maintenance and service contracts available

- 12-month warranty with all Feeding Systems

Applications

Technical specifications

Rec. production capacity

Up to 25,000 products daily

Maximum product throughput

40/min

Product size minimum (W x L)

60 x 60mm

Product size maximum (Wx L)

350 x 350mm

Dimensions (L x W x H)

1285 x 595 x 475mm

Net weight

90kg (200lbs)

Success stories

Resources

Related products

Talk with an expert

Book a demo and unlock the potential of Rotech's coding & marking technology.